How AI is Transforming the Manufacturing Industry Forever

1. Introduction

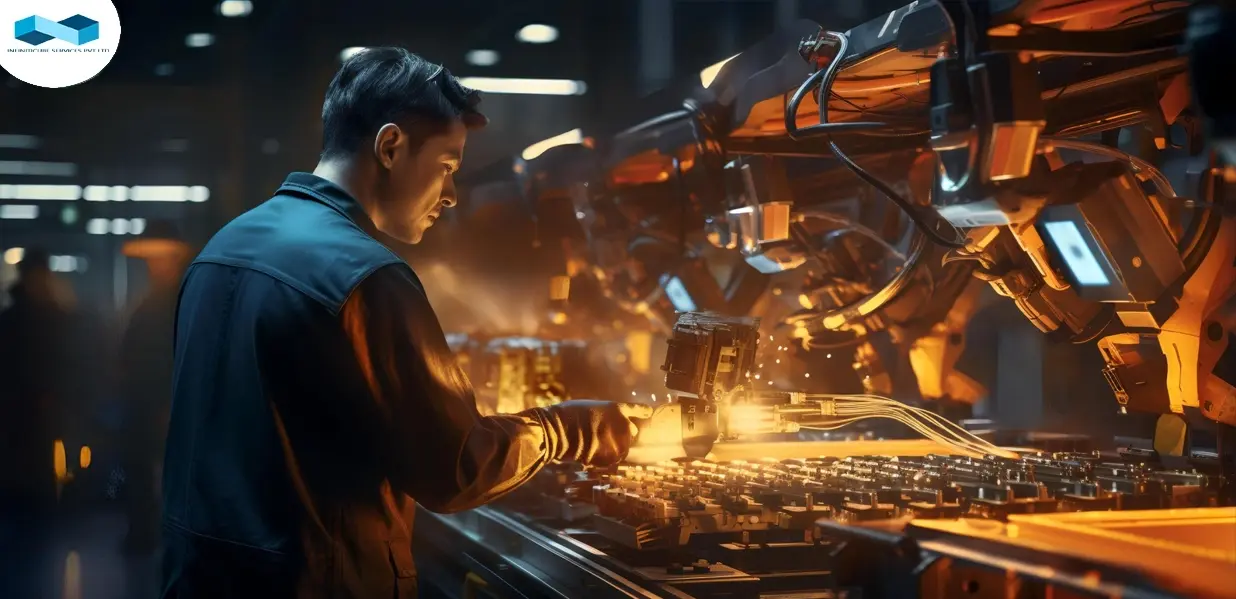

Artificial intelligence (AI) is revolutionizing manufacturing through data analysis, efficiency improvements, innovation, quality control, and human-machine collaboration. AI optimizes processes, predicts maintenance issues, customizes products, and enhances productivity.

The integration of AI in manufacturing leads to smart factories where machines communicate, adapt, and innovate in real-time. AI-driven quality assurance techniques detect defects early, reducing waste and ensuring consistent product quality.

Collaborative robots work alongside humans, enhancing safety and efficiency. Embracing AI in manufacturing unlocks efficiency, competitiveness, and innovation, requiring strategic investments and continuous learning for success in the evolving landscape. AI and human ingenuity together shape the future of manufacturing.

2. Revolutionizing Manufacturing Operations

AI is transforming manufacturing operations by enhancing efficiency, supply chain management, quality control, predictive maintenance, and production planning. Automation replaces manual tasks, AI optimizes workflows, reduces costs, and improves operational efficiency.

Discussion on how AI is revolutionizing various aspects of manufacturing operations

AI in supply chain management provides real-time insights, optimizes procurement, and mitigates risks. Quality control is improved through AI-based inspection technologies and machine learning algorithms.

Predictive maintenance predicts equipment failures, minimizes downtime, and optimizes equipment performance. AI enables agile production planning to adapt to demand fluctuations and market dynamics.

Manufacturers can achieve new levels of efficiency, agility, and innovation by harnessing AI technologies in every aspect of manufacturing operations. The transformative impact of AI on manufacturing will continue to deepen, driving unprecedented productivity and competitiveness in the industry.

Industrial AI: Empowering smarter and more efficient factories

- Industrial AI revolutionizes manufacturing, enhancing efficiency and productivity with advanced technologies.

- AI optimizes processes, automates tasks, and adapts to changing demands for informed decisions.

- Enhances operational efficiency by analyzing data, identifying inefficiencies, and optimizing workflows.

Predictive Maintenance: Preventing downtime and optimizing machinery performance

- Predictive maintenance anticipates failures, minimizes downtime, and extends machinery lifespan with proactive monitoring.

- Machine learning extracts insights from data to predict equipment failures and optimize maintenance strategies.

- Implementing AI-driven maintenance requires technology, data integration, and organizational change for improved efficiency.

- Industrial AI empowers factories to be smarter, more efficient, and resilient, driving innovation in manufacturing.

Production Optimization: Maximizing efficiency and reducing waste

- Production optimization is crucial for efficient factory operations

- Industrial AI utilizes data analytics and machine learning to fine-tune processes

- Predictive modeling and real-time monitoring help identify bottlenecks and streamline workflows

- Lean manufacturing principles combined with AI-driven insights maximize efficiency and reduce waste

Quality Control: Enhancing product quality through AI-based inspection

- Industrial AI improves inspection with advanced technologies

- AI systems analyze data, sensor readings, and visuals

- Automation and AI-driven measures ensure consistency and reliability

- Continuous monitoring enhances quality and minimizes defects

- AI safeguards brand reputation by detecting anomalies in real-time

Safety Measures: Improving workplace safety using AI technologies

- Industrial AI enhances workplace safety using sensors, computer vision, and predictive analytics

- Monitors equipment, detects anomalies, and alerts personnel to potential hazards in real-time

- Empowers factories to prioritize employee safety while optimizing operational performance

- AI technologies enable proactive interventions for predictive maintenance and ergonomic design

- Optimizes production processes, enhances product quality, and improves workplace safety

- Harnesses data analytics and machine learning for operational excellence and competitiveness

- Evolving Industrial AI revolutionizes manufacturing operations, driving innovation and industry progress.

3. AI Applications and Benefits

Artificial Intelligence (AI) is revolutionizing manufacturing with innovative applications and efficiency improvements.

Exploration of the diverse applications and benefits of AI in manufacturing

- AI enhances manufacturing with predictive maintenance, quality control, and data analysis for optimization.

- AI-powered robotics streamline tasks, boosting productivity and scalability.

- Machine learning provides insights on consumer trends, demand forecasting, and market dynamics.

Supply Chain Management: Enhancing visibility and responsiveness in supply chains

- Effective supply chain management is crucial in the global economy

- AI provides real-time visibility and predictive insights for proactive decision-making

- AI optimizes inventory levels, streamlines logistics, and minimizes disruptions

- Demand forecasting accuracy improves production planning and reduces costs

- Resilient supply chains can adapt to market changes and enhance customer experiences

Energy Efficiency: Reducing energy consumption and promoting sustainability

- Sustainability in manufacturing focuses on reducing energy consumption and environmental impact

- AI optimizes resource utilization, minimizes waste, and integrates renewable energy

- AI algorithms enhance equipment performance, regulate energy consumption, and identify inefficiencies

- Predictive maintenance by AI improves equipment reliability, reducing downtime and conserving energy

- AI helps align with environmental regulations, enhance brand reputation, and reduce carbon footprint

- Integration of AI in manufacturing leads to innovation, efficiency, and sustainability

- AI optimizes operations, streamlines supply chains, and promotes environmental stewardship

- AI's impact on manufacturing drives industry advancements and shapes the future of production

Predictive Analytics: Forecasting demand and optimizing production planning

- Predictive analytics in manufacturing uses AI algorithms to anticipate market trends and forecast demand.

- Analyzing historical data, consumer behavior, and market dynamics enables accurate production planning.

- AI-driven predictive analytics helps adjust schedules, allocate resources efficiently, and reduce inventory costs.

- It identifies supply chain disruptions, addresses bottlenecks proactively, and enhances customer satisfaction.

Data-driven Decision Making: Leveraging real-time data for strategic insights

- Data-driven decision-making is essential for competitive advantage in Industry 4.0.

- AI enables real-time data utilization for informed strategic decisions.

- AI algorithms analyze data, identify patterns, and optimize resource allocation.

- AI-driven decisions improve agility, responsiveness, and innovation.

- Enhances operational efficiency and drives continuous improvement for sustainable growth.

Environmental Impact: Addressing environmental concerns through AI-driven initiatives

- Manufacturers use AI to reduce carbon footprint and address environmental concerns

- AI optimizes energy consumption, waste reduction, and eco-friendly practices in production

- AI identifies energy efficiency opportunities, optimizes supply chain, and reduces greenhouse gas emissions

- AI enables development of sustainable solutions like renewable energy integration and waste recycling

- AI in manufacturing drives innovation, efficiency, and sustainability, shaping the industry's future.

4. Challenges and Future Outlook

This section discusses challenges and future prospects for AI in manufacturing. It emphasizes acknowledging obstacles and forecasting industry impact.

Identification of challenges and barriers to AI adoption in manufacturing

- AI adoption in manufacturing faces challenges like lack of skilled personnel, data privacy concerns, and high upfront costs.

- Cultural resistance and organizational inertia also hinder AI adoption in manufacturing.

- Solutions include investing in education and training, enhancing data security, and fostering innovation culture.

Speculation on the future trajectory of AI in the manufacturing industry

- Future of AI in manufacturing promising, offers innovation and growth opportunities

- AI advancements enable predictive maintenance, optimize production, and reduce reliance on manual labor

- AI enhances quality control, improves product consistency, customer satisfaction, and brand reputation

- AI combined with 5G, IoT, and AR has potential to transform manufacturing operations and drive competitiveness

- Challenges exist, but with innovation culture, AI can boost efficiency, productivity, and sustainability in manufacturing

Labor Adaptation: Addressing workforce implications of AI integration

- Integrating AI in manufacturing poses challenges for the workforce

- Concerns include job displacement and the need for upskilling

- Manufacturers should invest in training and lifelong learning initiatives

- Empowering employees to work with AI can enhance productivity

- Collaborative robots enable humans and machines to work together synergistically

Regulatory Considerations: Navigating regulatory frameworks for AI implementation

- AI integration in manufacturing requires navigating complex regulatory frameworks

- Regulators struggle to establish clear guidelines for ethical AI deployment

- Manufacturers must comply with evolving regulatory standards to mitigate legal risks

- Address data privacy, security, and algorithmic bias for ethical AI implementation

- Collaboration with regulatory bodies and legal experts is essential for compliance

- Prioritize workforce development and ethical AI principles for successful AI integration

- Strategic planning and collaboration can help shape a positive future with AI in manufacturing

Technological Advancements: Anticipation of future AI advancements and innovations

- AI evolving rapidly in manufacturing

- Challenge to keep up with tech advancements

- Focus on machine learning, edge computing, quantum computing

- Invest in R&D and collaborate for innovation

- Embrace emerging tech for competitiveness and growth

Ethical and Social Implications: Considering ethical implications of AI in manufacturing

- AI in manufacturing offers efficiency but raises ethical concerns like job displacement and inequality

- Challenges include algorithmic bias, data privacy, and transparency in decision-making

- Stakeholder engagement crucial for addressing ethical concerns and establishing guidelines

- Prioritizing ethical principles builds trust in AI technologies and mitigates risks

- Proactive innovation and ethics essential for navigating AI landscape and driving positive change

5. Conclusion

Artificial Intelligence (AI) is revolutionizing manufacturing, enhancing efficiency, quality, and safety. It's a catalyst for innovation and growth, offering opportunities for optimization, cost reduction, and increased productivity. Embracing AI is crucial for sustainable growth and competitiveness. AI can transform operations through predictive maintenance, data-driven decisions, and supply chain optimization, paving the way for innovation and growth in the manufacturing sector. The future is promising with AI as a powerful ally.

Curious about how AI is reshaping manufacturing for good?

Dive into our insights on how AI is transforming the manufacturing industry forever. Ready to revolutionize your operations? Reach out today and join the future of manufacturing!